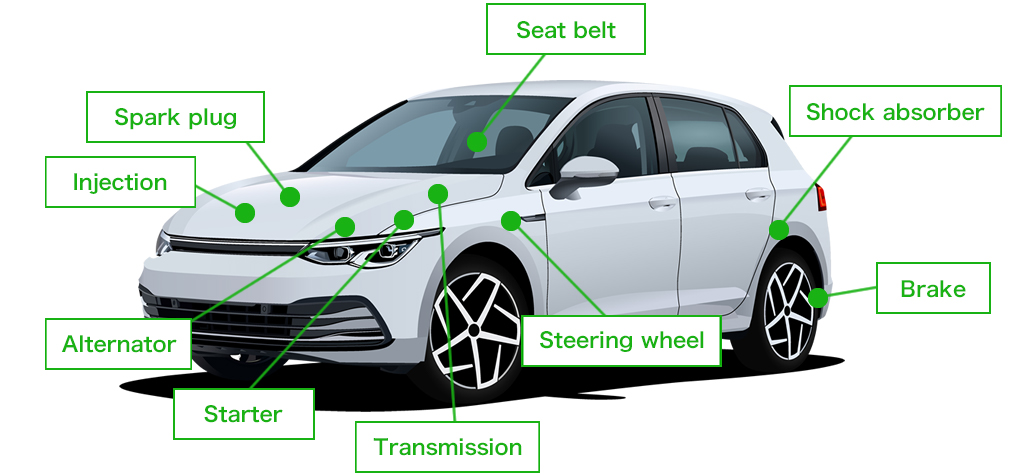

Cold forged parts

Feature of Osaka Seiko

Osaka Seiko manufactures a variety of cold forging parts that are used in automotive industry. We are able to produce cold forging parts from 2mm to 55mm in wire size. All are produced and accomplished in strict conformance to the requirements of our customer specifications

Feature of Osaka Seiko

-

01

Process Planning

Osaka Seiko cooperates with customers discussing part shape,size,accuracy,material from the development stage of new products.

It is one of Osaka Seiko’s attributes to not only design the forging dimensionally, but to suggest material and production process of CHQ wire.

This makes it possible to produce precision cold forging parts and to meet customer’s requirements and characteristics of product which customer produces.

We challenge the underdeveloped and frontier areas of cold forging processes. -

02

Equipment

Osaka Seiko provides a wide range of production capability fromφ2 toφ55 material processing formers which covers all types of automobile parts produced from CHQ wire.

In addition to meet the specific needs of our customers for more complex shapes and larger, we have 1100KN, 2500KN and 6300KN Press machines.Forging capacity φ55~φ2 Supply wire size

(Cutoff Dia.)400KN~1,000KN Weight 0.5kg ~ 2.0kg Other Equipments

- NC machine

- Theread rolling machine

- Centerless grinding machine

- Pickling & Coating

- Shot blast machine

- Barrel finishing machine

-

03

Branch factory

Name Aiken Precision Technologies LLC Address 50 Beloit Street, Verenes Industrial Park, Aiken, SC 29805 >>MAP Phone (803)641-2095 Fax (803)641-2096

Feature of Osaka Seiko

Precision Products of Gear and Serration

Backward Extrusion Products with High internal Quality and Complicated Shapes

Forward Extrusion Products

Precision Products with Long shaft and Long(deep) hole

Precision Products with large diameter

Slugs