Strong point of Osaka Seiko

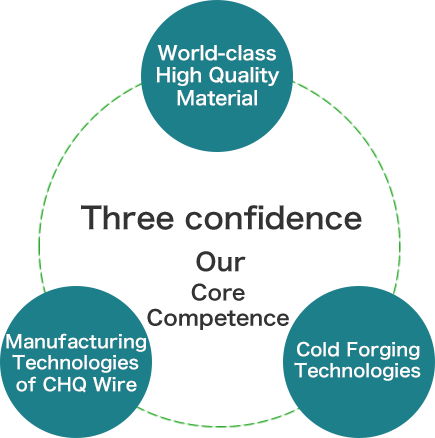

One-stop support for everything from steel wire manufacturing to automotive parts manufacturing and processing.

We work on improving ability in technical service and suggestion by making the most of the expertise and manufacturing technologies that gained through manufacture of wide variety of CHQ steel wires and Cold forging parts specializing in the automotive industry.

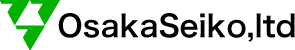

Three confidence - Core Competence

Core Technology

=

Manufacturing Technologies of Cold Heading Quality Wire

Cold Forging Technologies

We consistently manufacture high quality and high precision products based on high quality materials supplied by Japanese Steel Maker, and high quality and high precision are attained through making the most of manufacturing technologies and experience.

Cold Heading Quality steel wire

- 1.Process design of CHQ steel wire designed to meet customer's requirement

- 2.Wide variety of steel grades and manufacturing engineering designs

- 3.Enhancement of technical service

Cold Forging Parts

- 1.Integrated manufacture to cold forging parts from CHQ steel wire

- 2.Manufacturing engineering designs that taken advantage of a wealth of data and long experience

- 3.Pursuit of Net-shape by making the most of Former and Press

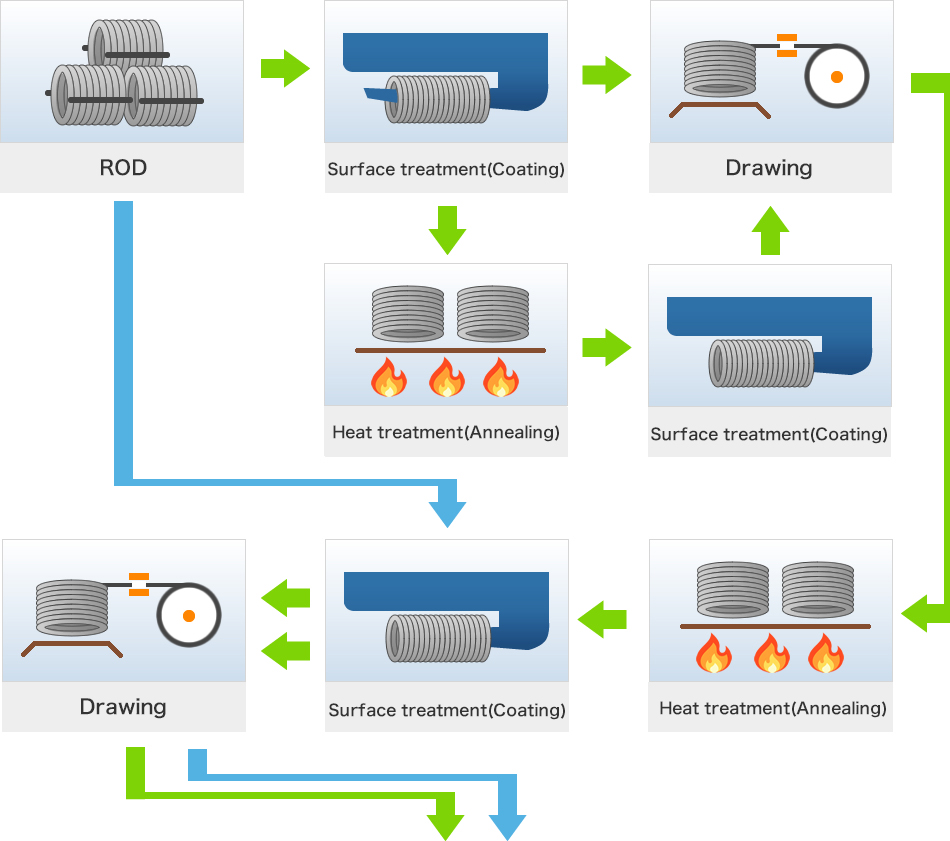

From CFQ Wire to Cold Forging Parts.

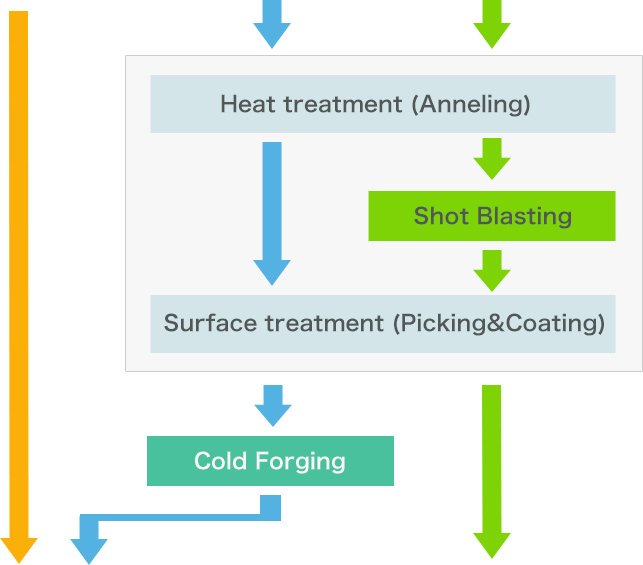

We are working on manufacturing CHQ steel wire that meet customer’s requirement (Size , Shape , Hardness , Surface quality) and characteristics of product which customer produces under optimum processes, Drawing , Rolling , Surface treatment(Pickling&Coating), Heart treatment(Annealing). In addition we manufacture Near Net Shape Cold forging parts and Cold forging slugs in house-made CHQ wire, by aking use of the holding equipments effectively.

Cold Forging(3~6stages)

Cold forging parts

Cold forging slugs